#REFLOW SOLDERING TEMPERATURE PATCH#

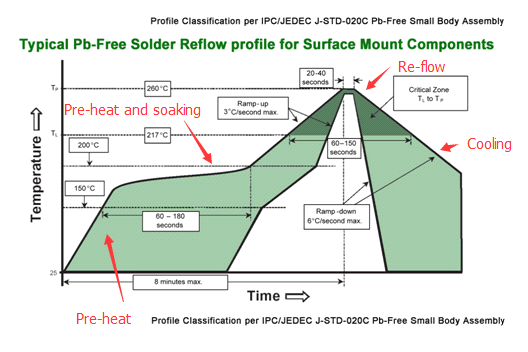

POE PCB in china has its own PCB assembly and patch processing plant, and the reflow oven is in ten temperature zones, which can meet the different needs of customers.ġ. Therefore, this article is only for reference, not a fixed temperature zone temperature standard. In fact, the temperature setting of the eight temperature zones is not fixed, it can also be flexibly adjusted, but the adjustment needs to be determined according to the quality of the SMT solder paste, the actual soldered product and the SMT reflow soldering machine. The temperature settings of these temperature zones also need to be adjusted according to the temperature curve reference value given by the solder paste manufacturer and the actual production situation. SMT reflow soldering eight-temperature zone temperature setting: 160☌ in the first zone, 180☌ in the second zone, 185☌ in the third zone, 185☌ in the fourth zone, 210☌ in the fifth zone, 250☌ in the sixth zone, 275☌ in the seventh zone, The eighth zone is 250℃.

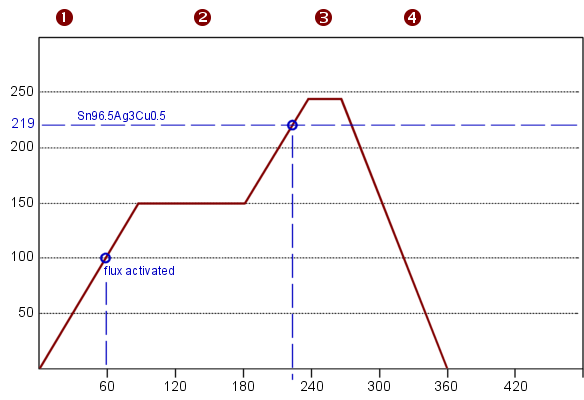

Cooling zone: the cooling zone time is about 100s, the temperature drops from 245 degrees to about 45 degrees, and the cooling speed is: 245 degrees-45 degrees = 200 degrees / 100S = 2 degrees / s. Recirculation zone: The high temperature of the recirculation zone is 245 degrees, the low temperature is 200 degrees, and the time to reach the value is about 35/S the heating rate of the recirculation zone is: 45 degrees/35S=1.3 degrees/S according to (how to The correct setting temperature curve) shows that: the time for this temperature curve to reach the value is too long.

Constant temperature zone: The high temperature of the constant temperature zone is about 200 degrees, the time is 80S, and the difference between high temperature and low temperature is 25 degrees.ģ. Preheating zone: the temperature of the preheating zone is raised to 175 degrees, and the time is about 100S, so that the heating rate of the preheating zone can be obtained.Ģ. So what are the differences between these temperature zones? What are their respective temperature standards?ġ. The temperature zone of lead-free solder paste SMT reflow soldering is generally divided into preheating zone, constant temperature zone, soldering zone and cooling zone. Usually The common SMT PCB assembly reflow soldering on the market is eight temperature zones. If the soldering quality requirements of circuit boards are relatively high, more manufacturers use SMT reflow soldering in ten temperature zones and twelve temperature zones. Generally speaking, the more SMT reflow soldering temperature zones, the better the soldering effect. This is determined according to the actual soldered products and the actual considerations of the SMT chip processing manufacturer. Of course, there are SMT reflow soldering machines in several temperature zones in actual use. Generally speaking, the standard SMT reflow soldering is the eight-temperature zone reflow soldering. The lens is held in place using a block of the alloy, which is then easily removed with hot water.Temperature zone standard for SMT reflow soldering Eye glass lens blocking is another application where low-temperature or fusible alloys work well. Low-temperature or fusible alloys are commonly used in a variety of safety devices where they are designed to melt at a peak temperature to initiate a process. The softness and malleability of indium, in addition to its ability to retain these characteristics at cryogenic temperatures, allows it to fill in imperfections in mating surfaces to create a hermetic seal. The sealing process uses mechanical pressure to create the bond. Some sealing operations use pure indium and require no heat at all. Typical applications for these materials include thermostats, switches, barometers, heat transfer systems, and thermal cooling and heating designs. Other advantages of these liquid alloy systems are their inherent electrical conductivity. This allows for the use of these materials in specific heat-conducting applications, such as heat dissipation in sensitive components during operation, machining, and/or manufacturing. SiP & Heterogeneous Integration & Assembly (HIA)Īlloy systems that are liquid at room temperature have a high degree of thermal conductivity, far superior than ordinary non-metallic liquids.The Indium Corporation & Macartney Family Foundation.

0 kommentar(er)

0 kommentar(er)